According to experts, Tesla is setting the new industry standard in electric vehicle production thanks to its one-piece chassis and 'unboxed' approach.

Tesla is setting the new industry standard in electric vehicle production thanks to its one-piece chassis and ‘unboxed‘ approach.

In the Toyota-Tesla rivalry brought to the agenda by the Financial Times, Elon Musk’s revolution in car production drew attention. According to experts, Tesla is setting the new industry standard in electric vehicle production thanks to its one-piece chassis and ‘unboxed’ approach.

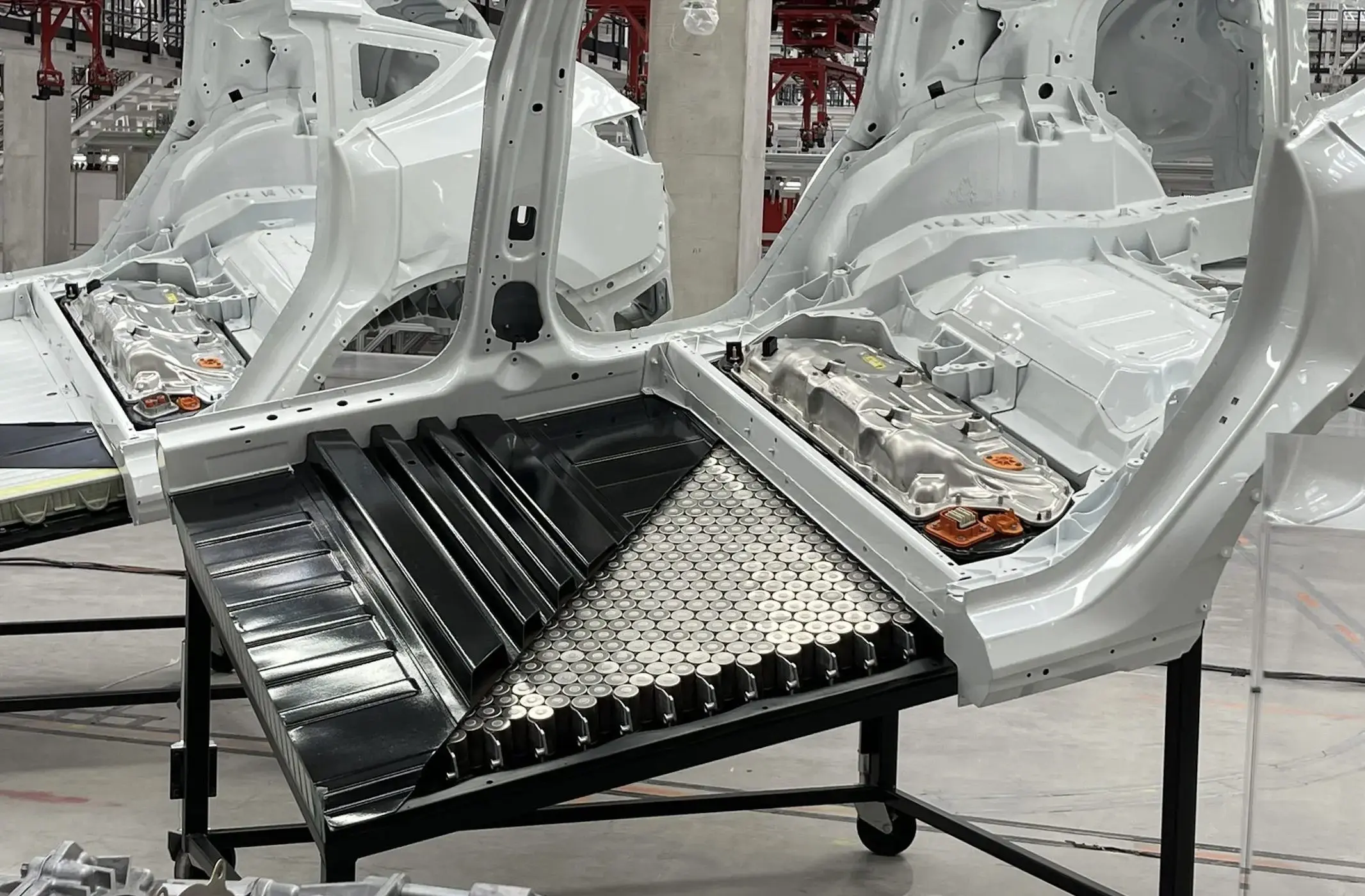

Instead of designing hundreds of parts to form the vehicle chassis, Tesla managed to produce the front and rear chassis in a single piece with giant aluminum casting machines. With this design, Tesla managed to impress world giants such as BMW, Volvo, Toyota, Volkswagen, and Hyundai, especially Chinese manufacturers.

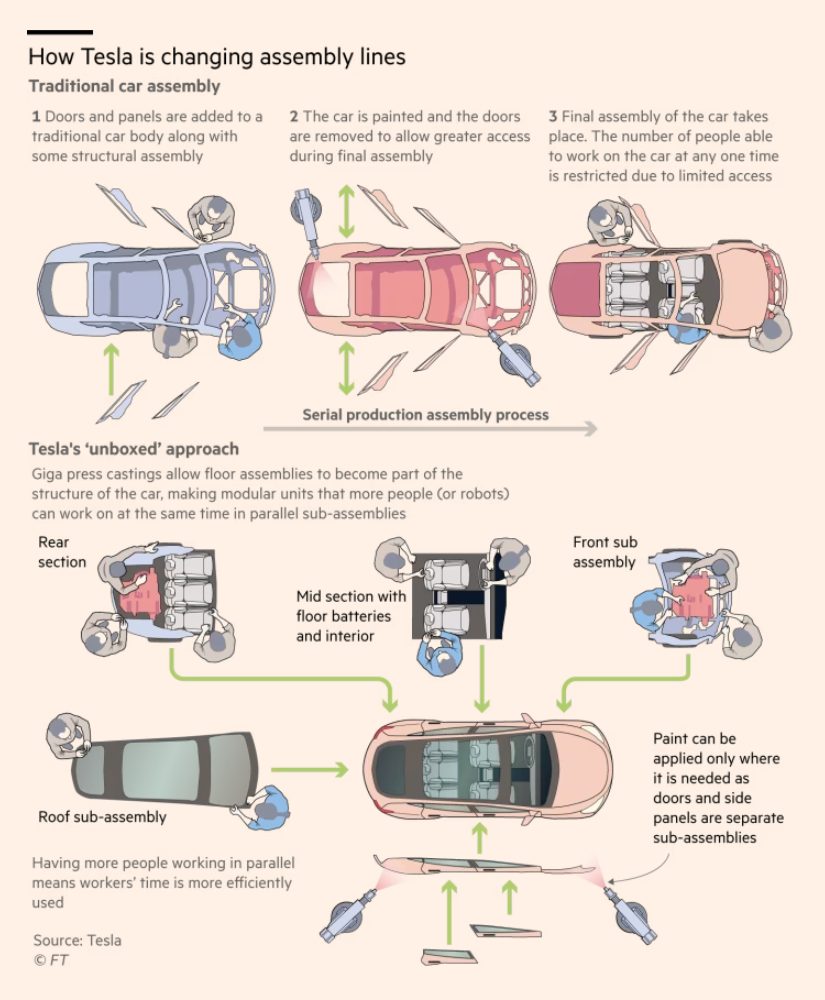

The one-piece chassis will lead to a transition to a more efficient method in vehicle assembly at the next level, instead of the Toyota approach that the industry has been following for many years. It makes it possible to produce cars in a shorter time with less equipment and personnel/robot arm in a smaller factory area.

Elon Musk shared the introduction of the third-generation vehicle platform at the beginning of the year. The ‘unboxed’ method allows more personnel to operate more efficiently by using working time more efficiently during the production of a vehicle.

In the Tesla-style vehicle assembly described in the footage, work is carried out on the front and rear chassis produced in one piece, while the seats and upholstery are assembled on the structural battery pack. In the approach, where the glass roof is prepared simultaneously and these four components are mounted on the pre-painted body, there is no need for the pre-and post-paint assembly/disassembly cycle in the existing car assembly line, and the completion time of the assembly is significantly reduced as more personnel work on different parts of the vehicle simultaneously.

Tesla wants to adapt this method to the chassis so that it will produce the entire vehicle chassis and some body elements in 2025 and beyond with hundreds of tonnes of casting machines with 18-20 thousand tonnes of compression force. The €25,000 Tesla will be able to be launched with much more advanced hardware and software than its competitors thanks to these and similar savings in production.